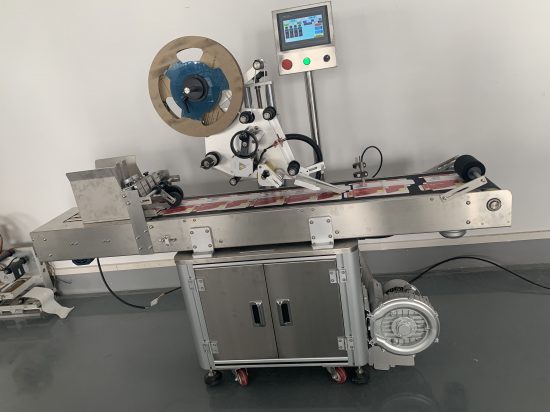

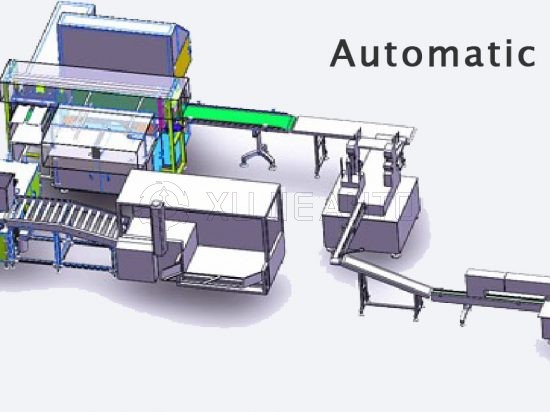

Plane labeling machine ** is a kind of automation equipment, which is specially used for affixing labels or non-adhesive film on the plane of various products, and is widely used in the plane labeling of large products such as books, folders, boxes, cartons, etc. The following will introduce the automatic plane labeling machine from the following aspects:

- ** Working principle ** : The work flow of the automatic flat labeling machine starts from the sensor detection of the product, returns the signal to the labeling control system, and after PLC processing, the label is sent out and attached to the product set position at the appropriate time. The entire process, including product delivery, correction, testing and labeling, is automated [^1^].

- ** Technical parameters and features ** : The technical highlights of the equipment include a wide range of application, high labeling accuracy, rugged construction, high stability, simple adjustment, flexible application, intelligent control and user-friendly touch screen operation interface. These features together ensure that the equipment can efficiently and accurately complete the labeling task [^1^].

- ** Structural composition ** : The main structure of the automatic plane labeling machine includes the parting mechanism, the main switch, the conveying mechanism, the receiving mechanism, the labeling mechanism, the labeling head, the touch screen and the electric box. Each mechanism has its specific function and works together to achieve a smooth labeling process [^1^].

- ** Application range ** : Automatic flat labeling machine is suitable for various types of labels, such as self-adhesive labels, electronic supervision codes and bar codes. Its application industries are very wide, including printing, stationery, food, daily chemical, electronics and medicine industries. In these industries, automatic flat labeling machines can play an important role in products that need to attach labels or films on flat or large curved surfaces [^1^].

- ** Operation process ** : To operate the automatic flat labeling machine, the user needs to follow a series of steps, including placing the product, starting the conveying mechanism, product correction and testing, performing the labeling action, covering the label, and collecting the labeled product. The whole operation process is simple and easy to master [^1^].

- ** Market hot products ** : There are other types of labeling machines on the market, such as automatic rotary CNC self-adhesive labeling machines, carton sealing labeling machines, oil drum labeling machines and round bottle positioning labeling machines, etc. These devices provide a variety of labeling solutions for different shapes and sizes of products [^2^].